The evolution of manufacturing technology has seen the development of techniques that allow for greater precision, efficiency, and creativity in production. As industries continually seek ways to improve products and processes, laser cutting in Brisbane stands out as a transformative method that is shaping the future of local manufacturing and fabrication.

What is Laser Cutting?

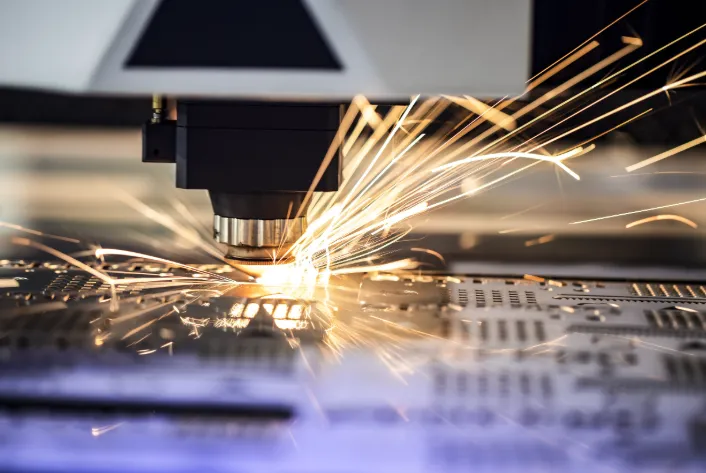

Laser cutting is an advanced fabrication method used to cut or engrave materials with exceptional accuracy. The technique involves directing a high-powered laser through optics to focus on a material, which then either melts, burns, vaporises, or is blown away by a jet of gas, leaving an edge with a high-quality surface finish. It has become a preferred method for many industries due to its unmatched precision and versatility.

The Advantages of Laser Cutting Technology

Adopting laser cutting Brisbane services provides numerous benefits. Firstly, the advanced technology achieves a higher degree of accuracy than traditional cutting methods, which translates to a reduction in material wastage. The precision of laser cutting allows for intricate designs and the ability to produce complex shapes with clean cuts and sharp edges, a feat that may be difficult to accomplish with other cutting techniques.

Laser cutters are proficient in handling various materials including metals, plastics, wood, glass, and even paper, which makes it ideal for a broad range of applications. Moreover, the process is automated and controlled by computer numeric control (CNC), enhancing repeatability and enabling mass production with minimal variance.

Fabrication using laser technology is fast and energy-efficient, decreasing turnaround times and energy costs in comparison to other processes. Furthermore, the contactless nature of laser cutting minimises damage to the workpiece, reducing the need for post-processing and ensuring products are market-ready faster.

Driving the Future of Fabrication

Laser cutting is at the forefront of Brisbane’s manufacturing revolution. The precision, speed, and flexibility of this technology foster innovation, allowing Brisbane’s engineers and designers to experiment with new materials and complex designs.

The city’s manufacturing sector benefits from the continuous advancements in laser cutting equipment, including increased automation and integration with Industry 4.0 practices. Real-time monitoring and internet-enabled control systems are enhancing production lines, leading to smart factories that offer higher levels of operational efficiency and productivity.

Moreover, the environmental impact of manufacturing is an ever-pressing concern. Laser cutting is inherently more sustainable than some traditional methods, as it produces less waste and often reduces the number of processes needed to complete a product. As the technology continues to advance, it is expected that further improvements will be made in reducing its ecological footprint.

Challenges and Opportunities

Despite its numerous advantages, the laser cutting industry in Brisbane is not without challenges. The initial investment in laser cutting technology and machinery can be significant. However, companies must weigh this against the long-term gains in efficiency, precision, and reduced labour costs.

As the global market becomes increasingly competitive, Brisbane’s commitment to adopting advanced fabrication methods like laser cutting will not only strengthen local industry but can also open doors for the city’s businesses to compete on an international stage.

Training and developing a skilled workforce adept in operating and maintaining high-tech laser equipment is also crucial for the success and growth of laser cutting services in the region. Collaboration between industry and educational institutions is needed to ensure that the local talent pool can meet the demands of a modern manufacturing environment.

Looking Ahead

As we look to the future of precision fabrication, it is evident that Brisbane is positioning itself as a leader in laser cutting technology. With an eye on innovation and sustainability, businesses in the city are transforming traditional manufacturing practices and paving the way for advancements in various industries.

Whether it’s creating intricate components for the aerospace sector, bespoke pieces for the arts and design field, or efficient parts for automotive manufacturing, laser cutting enables Brisbane manufacturers to deliver exceptional quality and performance.

The city’s industrial landscape is undergoing a transformation, fuelled by laser cutting technology that provides the balance between high-speed production and meticulous attention to detail. As Brisbane continues to harness the potential of laser cutting, it not only enhances its reputation as a hub of modern manufacturing but also contributes to a future where precision is paramount.

To remain at the cutting edge, Brisbane manufacturers must continue to invest in and evolve with the latest laser cutting technology. By embracing the most advanced systems and continuously innovating, they will ensure that the local sectors stay competitive and sustainable in a fast-changing global economy.

In conclusion, the future of laser cutting in Brisbane looks bright, with the potential to drive significant change in the city’s manufacturing capabilities. Precision, efficiency, and innovation will remain the keystones of this technology as it cements its place as a vital part of the industry’s evolution. As businesses and industries recognise the inherent benefits and opportunities, the proliferation and advancement of laser cutting Brisbane technologies are set to soar, shaping the future of local and global production for years to come.

Author: Adlore